- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 48 Author: Site Editor Publish Time: 2021-05-31 Origin: Site

Machine Installation

When you receive the machine, open the package, check the accessories in Packing list with the machine. If quantity is not correct, please contact us. We will resend again.

1)Open the machine package

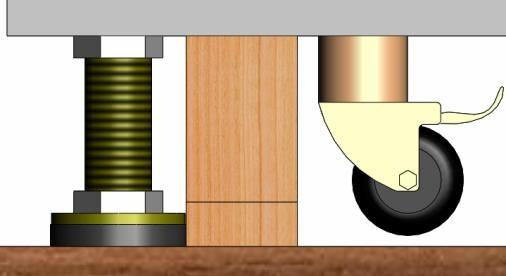

2) Loosen the upper nuts of the feet with a wrench, and raise the feet to make the distance to the pallet greater than to the casters.

Figure Loosing Casters and Feet

3) Fork the machine from the pallet with a forklift, deliver to the destination, and unscrew the feet.

Environmental requirements for installation

The installation site must be away from dust, dirt, humidity, and rain. The floor to be placed must be flat and capable of carrying loads,

Preference is given to floors with sound-attenuating coverings to prevent the transmission of mechanical vibrations.

The power connection, air compressor or air source at the installation site must be consistent with the required specifications.

Power distribution specifications:

1) Rated power 11KW,

2) The power cord is three-phase three-wire, 6-10 square millimeters.

3) Leakage circuit breaker 200V-240V/60HZ-63A. Install to 3-8 meters away from the machine.

4) Compressed air: pressure 0.4-0.7MPa, air pipe diameter 6MM;

Main accessories:

1) Electrical oscillating cutting head

2)1 USB data cable, 1 network/web cable

3) 20 cutting knives

4)One USB flash drive with machine control software and typesetting software, manuals and videos

5)A set of tools

Electricity connection

1) Machine input power connection

Open the back electrical box of machine, Connect 220V-240V/60HZ voltage three phase as

Figure shows

Figure: Machine Electricity connection

Vacuum pump installation and electricity connection

1)vacuum pump installation

Figure : Vacuum pump installation

2)Vacuum pump electricity connection to machine